Page information

OSM Series

Oil Skimmer OSM Series

Description

Description

Keyword

FAN installation, odor and decay prevention, tool lifespan extension, post-processing cost reduction, discoloration and fading prevention

Where to use

Applicable to all machines with floating oil in CNC lathes, machining centers, washing tanks, grinders, and cutting fluids.

Features

Product Features

-

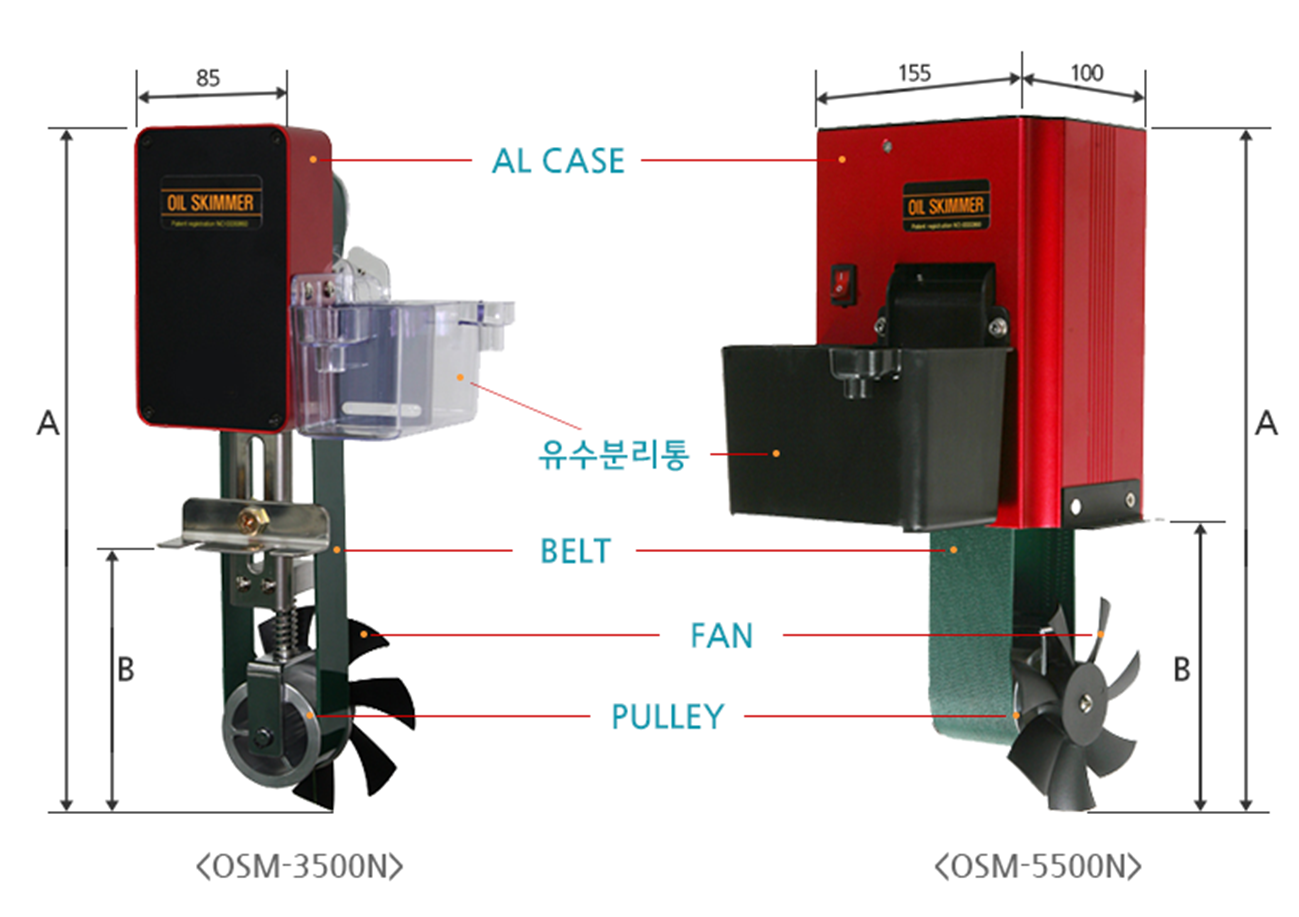

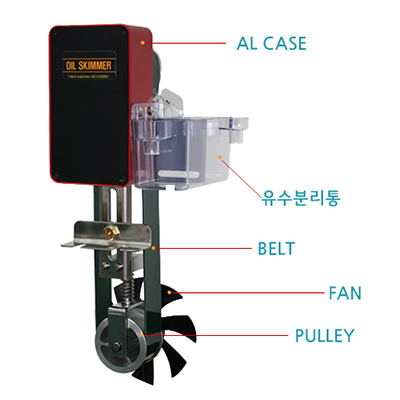

- AL CASE: Special coating and surface treatment to prevent corrosion from cutting fluid. BELT: Uses urethane belt to enhance processing efficiency.

- FAN: Prevents spoilage through the circulation of cutting fluid. The installation of the FAN initiates the circulation of cutting fluid, removing distant oils and other floating debris (Patent 0022747).

- PULLEY: Surface-enhanced with robust aluminum material. Features automatic tensioning function via a spring.

- Prevents the unique odor and spoilage of cutting oil, improving work efficiency and reducing waste oil disposal costs. Removes fine chips to extend tool life and enhance the surface finish of workpieces.

- Prevents oil accumulation on product surfaces, reducing post-processing costs. Effectively prevents discoloration and fading of materials during SUS or aluminum processing.

Video

Installation examples

View more

Fabrication, Installation, Licensing

One-Stop Support Autolink Inc.

Product inquiries and after-sales service

- Previous postHyrock Series 24.10.07

- Next postOilSkimmer SE Series 24.10.07

List of comments

No comments have been registered.

구매하기

구매하기